Aluminum checkered floor plate

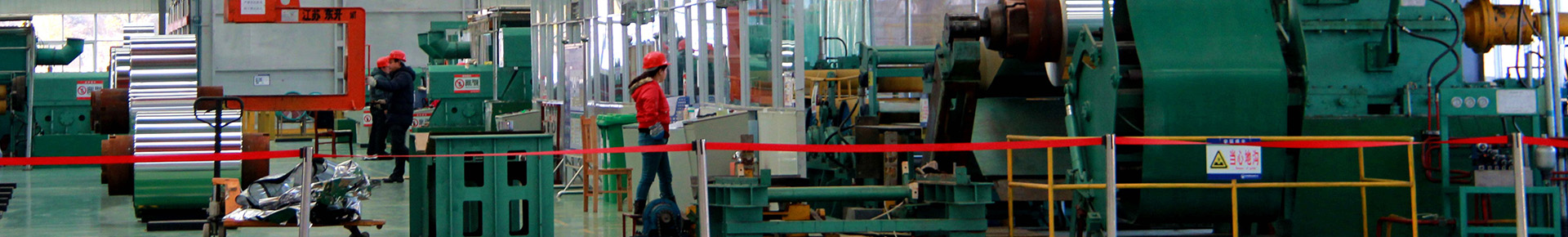

Aluminum checked floor plate is widely used in architectural decoration, transportation, shipbuilding and other fields. Cold rolled strip produced by cast rolling method ‚ Compared with ingot hot rolling strip method ‚ It has the advantages of simple process flow, less equipment investment, low energy consumption and low product cost ‚ It can produce pure aluminum and soft alloy strip blank ‚ At present, it has been widely used in aluminum rolling industry. However, the aluminum checked floor plate produced by cast rolling strip under the same cold rolling process conditions has some defects, such as insufficient pattern height, insufficient ribs, pattern offset, poor surface quality and so on. Therefore, taking 1100 aluminum alloy cast rolling strip blank as an example to produce 2 ∙ 0mm thick five strip pattern plate ‚ The quality of casting billet, intermediate annealing system, cold rolling parameters and emulsion lubricants which may affect the quality of embossing were analyzed. ‚ In order to improve the quality of pattern plate.

Aluminum checkered floor plate

Aluminum checked floor plate produced by cast rolling strip blank ‚ The blank shall be pre annealed ‚ Eliminate the intragranular segregation caused by casting and rolling ‚ Complex organizational structure and other defects. Cast rolled strip blank produces checkered plate with the same thickness as hot rolled strip blank ‚ The thickness of raw material should be increased by 10 ~ 15um.

The intermediate annealing temperature of cast rolled strip checkered plate is generally 40 ~ 80 ℃ higher than that of hot rolled strip ‚ Holding time 2H; It can also be used

High temperature rapid annealing increases nucleation rate ‚ Grain refinement ‚ Ensure annealing quality.

The embossing process uses a lower rolling speed ‚ The general control is 1 ∙ 2 ~ 1 ∙ 5m / s ‚ Ensure that the metal embossing stays in the deformation area for a long time ‚ The tension shall be subject to the flat belt ‚ It is convenient for pattern forming.

Embossing process ‚ High temperature in deformation zone ‚ The pattern belt teeth have strong adsorption capacity ‚ The ingredients of emulsion decreased greatly. ‚ The base oil and essential oil acid shall be supplemented in time according to the production situation ‚ Maintain a concentration of 22% and a temperature of 48 ℃ ‚ At the same time, strengthen the cleaning and filtration of emulsion.

The practice shows that by adjusting the cold rolling process parameters and changing the production conditions ‚ The cast rolled strip can also produce flowers of the same quality as the hot rolled strip striated plate.

Hot Spot :

- Features of aluminum checker plate sheet

- What are the types of aluminum checker plate?

- what is the difference between aluminum tread plate

- Orange peel aluminum plate

- Hemispherical pattern aluminum sheet for thermal di

- Cheapest aluminium checker plate

- Diamond tread plate aluminum sheets

- 6061 T6 aluminum tread plate

- 3003-H22 Aluminum Diamond Tread Plate

- Aluminum checker Plate Sheet

- Aluminium tread plate price

- Aluminum diamond plate for boat floor

- Best aluminum for boat floor

- Aluminium sheet for boat floor

- Aluminium bus floor sheet

- aluminum sheet flooring

- 3003 aluminum floor plate

- 5754 Aluminum floor plates

- Production processing of aluminum tread plate

- Hemisphere aluminum stucco sheet for heat dissipati

- Super width aluminum tread plate

- 5754 H114 aluminum diamond plate

- Matte Black aluminum Diamond Plate

- 4017 aluminum plate sheet

- Ball embossed aluminum plate for heat dissipation

- Aluminum tread plate suppliers

- Black anodized aluminum diamond plate

- Black diamond plate for trailer

- Black diamond plate for trailer

- Lentil-shaped aluminum sheet

- Hammer tone Aluminium sheets

- 1/4 aluminum diamond plate

- How to clean Oxidized aluminum diamond plate

- How to protect aluminum diamond plate

- How to identify Aluminium chequer plate sheets?

- Application of Aluminium diamond tread plate on sta

- Selection of diamond tread aluminum sheet

- how to clean aluminum diamond plate floor

- Aluminum topgrip floor plate

- Aluminium floor sheet

- Diamond plate sheets for trailer floor

- Aluminum trailer fenders diamond plate

- Aluminium chequer plate cut to size

- 6mm aluminium floor plate

- Aluminum chequered plate for platform

- Aluminium checkered floor plate

- Rice grain aluminum floor plate

- Rice grain aluminum plate

- Aluminum chequer plate flooring

- Aluminium floor plate

- Aluminum checkered floor plate

- Aluminum traction tread plate

- Aluminum traction plate

- Aluminium sheet for trailer floor

- Aluminum diamond plate sheets for trailer floor

- Aluminum checker plate sheets

- Matt Black 5 bar aluminum tread plate

- Thinnest aluminum diamond plate

- 3003 H22 aluminum diamond plate

- Bright aluminum tread plate

- 6061 t6 aluminum tread plate

- 4017 Aluminum checker checkered plate

- 4017 aluminum diamond plate

- Diamond cut aluminum sheets

- Diamond Aluminum Plate Sheets For Trailers

- Aluminum tread plate for tool box

- Aluminum checker plate for trailer

- Marine grade aluminium checker plate

- Aluminium checker plate roll

- Aluminium chequered plate sheet

- Aluminium chequer plate price

- 3mm Aluminium Checkered Sheet Price

- Duet aluminum tread chequered plate sheet

- how to polish aluminum tread plate

- how to clean aluminum tread plate

- 5mm 6mm aluminium tread plate

- aluminium door tread plate

- aluminium 5 bar chequer tread plate

- aluminium 5 bar chequer plate

- aluminium chequer plate sheet

- 5mm 6mm aluminium checker plate

- aluminium checker plate price

- aluminium checker plate 3mm

- 4017 five bar aluminum tread plate

- embossed aluminum diamond plates sheets

- 0 25 aluminum diamond plate 4x8 sheet

- aluminum diamond plate sheets

- aluminum diamond plate for trailer floor

- powder coated aluminum diamond plate

- aluminum tread plate for trailer

- 5 bar aluminum tread plate supplier

- aluminum diamond plate for sale

- diamond embossed aluminum sheet

- embossed aluminum tread plate

- embossed aluminum diamond plate sheet

- embossed aluminum diamond plate sheet

- aluminum diamond plate for trailer floor

- teardrop aluminum plate for trailer

- aluminum diamond plate flooring for trucks

- aluminum diamond plate sheets for trailers

- Aluminum diamond plate 4x8 sheet

- Black Aluminum Diamond Plate Sheet

- anodized aluminum tread plate

- aluminum diamond plate wall panels

- aluminum tread plate sheets

- grain aluminum plate

- rice grain aluminum tread plate

- 4017 H22 brite aluminum tread plate

- cheap aluminum tread plate

- 3003 aluminum tread diamond plate

- aluminum tread plate running boards

- aluminum diamond plate boat floor

- thin aluminum diamond plate sheets

- diamond tread plate aluminum sheets

- aluminium tread plate rice grain

- embossed aluminum diamond plate

- slip not diamond plate flooring

- aluminium checker plate cut to size

- aluminium checker plate for caravans

- Aluminum chequered plate price

- anti slip aluminum stair treads

- embossed aluminium diamond plate sheet

- aluminum checker plate suppliers China

- aluminium diamond plate polishing

- Perforated aluminum planking China

- Anti slip aluminum walkway grating China

- Performated aluminum planking China

- .063 aluminum diamond plate

- 6061 T6 aluminum tread diamond plate

- aluminum anti skid plate

- non slip aluminum flooring plate planks

- non slip aluminum checker plate

- Anti slip aluminum sheet

- Anti-Slip Aluminium tread checkered plate

- Aluminum Non Slip Stair Treads

- slip resistance diamond aluminum plate

- slip not diamond aluminum plate stair treads

- slipnot aluminum tread diamond plate

- slipnot aluminum tread diamond plate

- aluminum tread brite diamond plate

- aluminum diamond checker plate for sale

- aluminum dock plates manufacturer supplier in China

- 5052 5083 3003 1100 aluminum dock deck plate board

- 1060 3003 5052 5083 aluminum checkered plate for de

- aluminum floor plate supplier manufacturer in China

- Black diamond plate sheets supplier manufacturer in

- China aluminum diamond plate manufacturer supplier

- Colored aluminum diamond plate

- Aluminum diamond plate trim

- 3003 black aluminum diamond plates

- Aluminum diamond plate flooring

- What is the aluminum diamond plate used for?

- Perforated- Anti-slip aluminum plate

- Why choose 5052 alloy to make marine grade aluminum

- Classification of aluminum diamond chequer plates

- introduction of the Aluminum tread checkered plate

- What's the effect of washing the diamond aluminum s

- The performance of 3003 aluminium checkered plate

- The cleaning of polishing aluminum diamond plate

- Advantage of pattern aluminium plate

- performance of 5052,6061 aluminium chequer plate

- The aluminium chequer plate sheet is used for ship

- Pattern aluminium plate integral style and colour c

- 1 8 aluminum diamond plate is used as platform peda

- Introduction of diamond aluminum plate sheet

- Application range of 5083 aluminum tread checker pl

- The application of aluminum tread diamond plate on

- Application range of 5083 aluminum checker board